Table of Content

How does neoprene look like? How is neoprene made?

Characteristics of Neoprene Fabric

Application of Neoprene Fabric

The History of Neoprene

The born of neoprene, back in the early 20th century, was because of a rubber shortage in the industry. DuPont, an industrial giant, associating scientists in the rubber&plastic field, invented “Polychloroprene” (neoprene), a type of synthetic rubber as an alternative to natural rubber, and made it into mass production in the 1930s. Neoprene was becoming widely used in World War II in terms of vehicle tires, floating bridges, gas and oxygen masks, medical equipment, boots, raincoats, shoes, etc.

Neoprene started to be used in wetsuits in 1951, boosted by Hugh Bradner, an American physicist, who had worked for U.S. Navy frogmen to retain body heat while staying in cold water for a long period of time. Initially, wetsuit neoprene was without lining, which was easily torn and difficult to put on and off. Afterwards, nylon and other fabric-lined neoprene started being applied in wetsuits to increase strength and smooth touch. Later, this one-lined or double-lined neoprene sponge is known as Neoprene Fabric or Scuba Knit and applied in various fields.

How does neoprene look like? How is neoprene made?

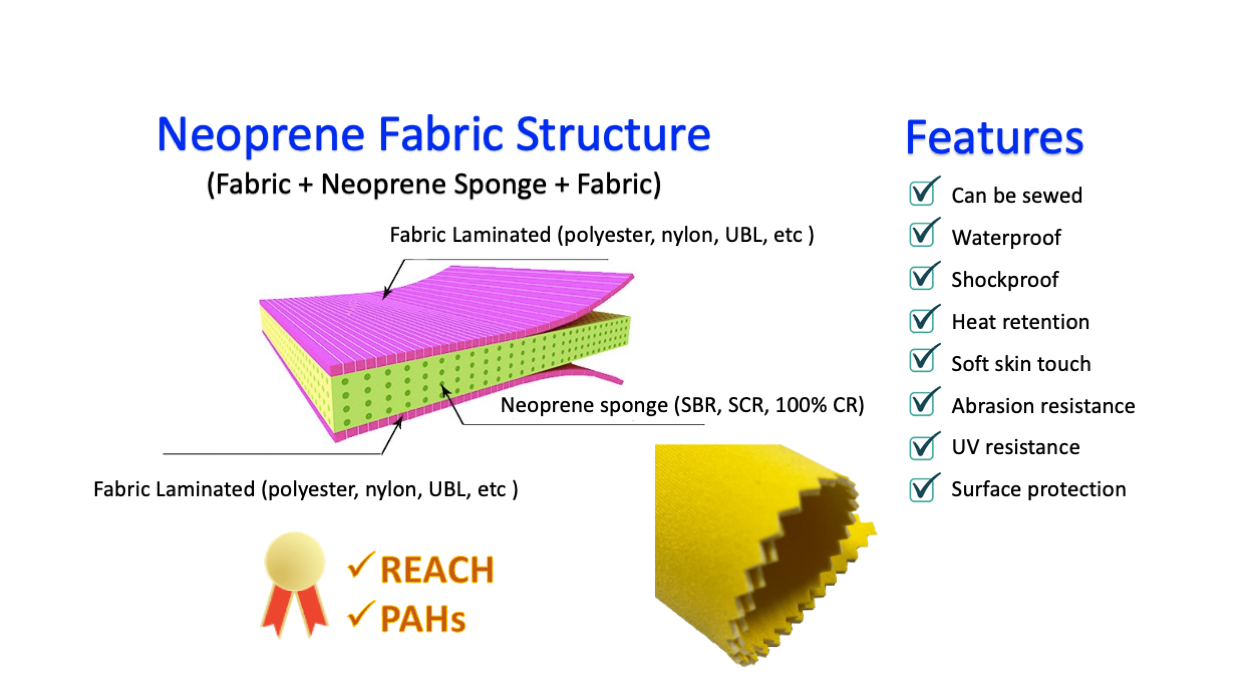

Basically, neoprene fabric is the neoprene sponge sandwiched between the fabric. Different from industrial neoprene, solid synthetic rubber, neoprene fabric is a closed-cell foamed synthetic rubber. After Polychloroprene chips are melted and mixed with various carbon pigments and foaming agents, the compound is put in an “oven” and “baked”. As a result of expansion, the neoprene foam is formed, from which the neoprene sheets are sliced up in the desired thickness. The video from “Macro International” illustrates how neoprene fabric is made.

Characteristics of Neoprene Fabric

The process of foaming makes neoprene soft, elastic, and be able to be sewed. Also, neoprene has the feature of waterproof, heat retention, and abrasion resistance, all of which make it a perfect material for water sports gear.

- Can be glued or stitched

- Stretchy

- Abrasion-resistant

- Heat-retention

- Weather-resistant

- Waterproof

- UV resistant

Application of Neoprene Fabric

Nowadays, beyond water sports garments, neoprene has been applied to various fields.

- Water sports gear

Diving suits, surfing suits, spearfishing suits, diving socks, gloves, swimsuits, triathlon, etc.

Feature: softness, elasticity, waterproof, heat retention and abrasion resistance.

The neoprene suitable for water garments includes Nylon Neoprene, Super Stretch Neoprene, Spandex Neoprene, Thermal Neoprene, Coated&Smooth skin neoprene.

- Orthosis&sports braces

Shoulder/knee/wrist/ankle braces, wrist splint, waist trainer, etc.

Feature: softness, durability, elasticity, heat retention, and abrasion resistance

The neoprene suitable for Orthosis&sports braces includes Nylon Neoprene, Small Diamond Neoprene, UBL fabric Neoprene, Perforated Neoprene.

- Electronic cases/Mats

Laptop sleeves, tablet sleeves, mouse mats, game mats, etc

Feature: light, surface protection, private printing, portable, and washable.

The neoprene suitable for electronic cases/mats includes Polyester Neoprene, Embossed Neoprene, Blank Neoprene, Printed Neoprene.

- Container cover

Coolers, stubby holders, lunch bags, water tank covers, etc.

Feature: insulation, private printing, light and portable.

The neoprene suitable for container cover includes Polyester Neoprene, Embossed Neoprene, Blank Neoprene, Printed Neoprene.

- Fashion bag

Tote bags, cosmetics bags, coin bags, etc

Feature: light, waterproof, private printing, portable, and washable.

The neoprene suitable for Fashion bags includes Polyester Neoprene, Perforated Neoprene, Blank Neoprene.

- Sports garments

Shapewear, waist trainer, sweatsuits, etc

Feature: light, stretchy, heat retention, and washable.

The neoprene suitable for Fashion bags includes Polyester Neoprene, Perforated Neoprene, Nylon Neoprene.