Factory Wholesale UBL Neoprene Fabric

One-stop solution of neoprene fabric and neoprene finished products!

You can find all the solutions from Vastop Neoprene. With a wide range portfolio and expertise in this field, we are known for satisfying various needs, supplying neoprene fabric with consistent performance and seamless delivery. Let me guide you through this solution page.

What is UBL Neoprene Fabric?

We are a company that values customers’ satisfaction.

We always aim at producing and delivering quality neoprene fabric that meets all your needs.

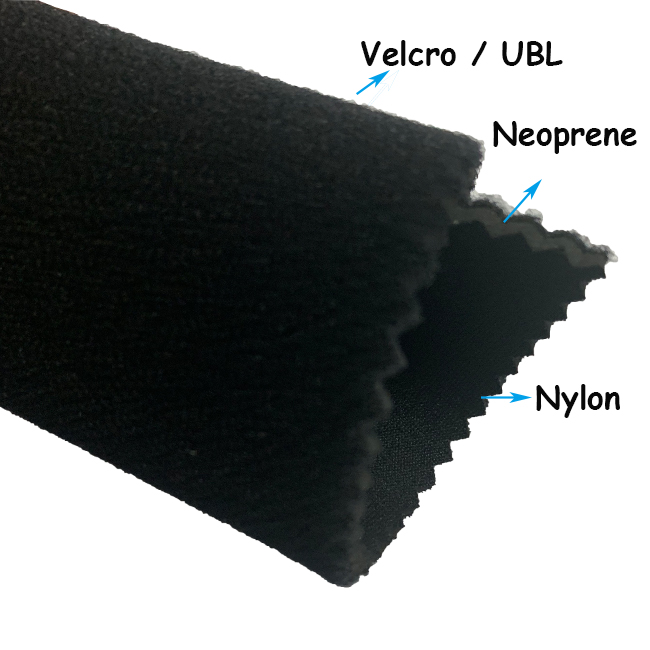

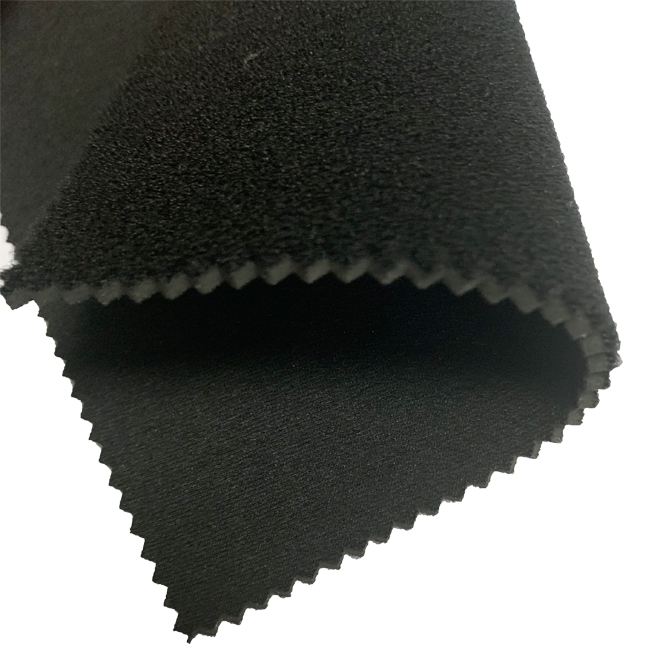

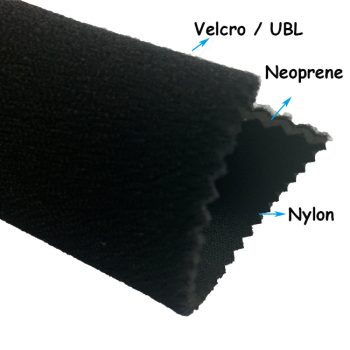

UBL fabric, also referred to as OK/plush fabric, blends nylon and spandex to create a versatile material with unbroken loops for effortless hook closure. When paired with neoprene sponge, it becomes an optimal choice for manufacturers in orthopedic and sports/animal gear industries, offering exceptional hook-and-loop fastening capabilities. Its full-surface “hookable” feature allows for flexible attachment, reducing the need for various sizes and safeguarding the neoprene fabric from fastener-induced damage. For manufacturers seeking top-notch neoprene fabric solutions, OK fabric stands out as a superior alternative to conventional hook-and-loop fasteners.

![]() There are three popular types of OK neoprene fabric.

There are three popular types of OK neoprene fabric.

| China Mainland OK neoprene fabric | |||||||||

| Feature: unbroken loop, budget-friendly, good stretchness and performance of hooking | |||||||||

| Application: orthopedics, sports braces, slimming waist trainers, animal protection gear, wetsuit, diving shoes, etc. |

| Taiwan OK Neoprene Fabric | |||||||||

| Feature: unbroken loop, medium price, medium stretchness and performance of hooking | |||||||||

| Application: orthopedics, sports braces, slimming waist trainers, animal protection gear, wetsuit, diving shoes, etc. |

| Japan OK Neoprene Fabric | |||||||||

| Feature: unbroken loop, high cost, excellent stretchness and performance of hooking | |||||||||

| Application: orthopaedics, sports braces, slimming waist trainers, animal protection gear, wetsuit, diving shoes, etc. |

![]() Specification of UBL Neoprene Fabric

Specification of UBL Neoprene Fabric

| Neoprene Sponge Type | Neoprene Sponge Color | Neoprene Sponge Hardness | Thickness | Size/sheet | Sublimation Print |

| SBR | Black, Aqua, Cream | 0-3°, 4-8°, 8-12° | 0.8-10mm | 51″x 130″, 58″ x130″ | Acceptable |

| SCR | Black, Cream | 0-3°, 4-8°, 8-12° | 0.8-10mm | 51″x 130″, 58″ x130″ | Acceptable |

| 100% CR | Black | 0-3° | 0.8-10mm | 51″x 83″ | Acceptable |

![]() Quality Assurance with Certificate

Quality Assurance with Certificate

| REACH | 201 substances in the Candidate List of Substances of Very High Concern (SVHC) passed the Regulation (EC) No 1907/2006 concerning the REACH. |

| PAHs | Comply with ZEK 01.4-08 of German ZLS. |

NB: We have a wide range of neoprene fabrics coming with different qualities. If you can’t find the one you want, please contact us for your specific requirements.

Wholesale Price

The criteria of all our solutions are to make sure the consistent product’s performance and help customers save money!

Contact us for a full price list.

Neoprene fabric cost. The cost of neoprene sponge and fabric cost, including lamination.

Optional costs include printing cost, embossment, perforation, or waterproof glue, etc if needed.

The standard packages, individual opp bags, are free. If pallets or crates are needed, a small amount fee will be charged.

We have rich logistic resources for samples and cargo delivery, which can optimize shipping means and minimize shipping costs.

How is UBL neoprene fabric made? Production Process

The below flow illustrates the production process of UBL neoprene fabric.

Step 1Slicing Up

Slice up Neoprene Sponge, 100% CR, SCR or SBR, from 40mm thick into the specific thickness of neoprene sheets, 0.8mm to 10mm.

Step 2Lamination

Laminate UBL fabric on one side of the neoprene sheets with glue and the other side is lined with nylon or other fabric.

Step 3Inspection

Inspect the neoprene fabric in terms of thickness, lamination and dimension, to make sure products meet all the order requirements.

Step 4Packing

Pack all products in roll or on pallets as required. Ready for shipment.

How can I get started? Order Procedure

I know the neoprene fabric I want or I know the application, how can I get started? Here is a guideline, where you can find the normal procedure ordering neoprene fabric.

01

Send an inquiry

Tell us about the neoprene fabric you are interested in, like fabric type, thickness, color, printing, applications, etc.

02

Discussion

Full understand the needs of customers and provide the proper recommendations and solutions.

04

Sample check

A sample is prepared for customers' evaluation, to guarantee the neoprene fabric meet all the requirements.

05

Start orders

With the approval of price and quality, we could confirm orders and the following procedure.

Things you need to know

To clear your concerns, here are some facts you need to know about neoprene fabric and us.

What’s the difference between Terry and OK fabric?

Some suppliers or customers might consider Terry fabric as OK fabric, while their effectiveness varies significantly. Compared to OK fabric, Terry is broken loop fabric, which has less elasticity, less performance of hooking, and low cost. Terry neoprene fabric and the brush neoprene fabric are often used for low-grade protection gear. However, terry fabric is a good material for the liner of devices sleeves, like laptop sleeves.

How do I know what OK fabric is good for my products?

According to your application and target markets, we will suggest the proper fabrics. After that, we highly recommend you test our samples by sewing or making a prototype to select the most suitable one.

P.S. There are multiple fabrics look similar on the market, and sometimes they don’t have a unified name which makes us confused. Therefore, if customers can give us a piece of sample to test, it would be the most straightforward way to figure out the materials you want.

Which grade of OK fabric is mostly used in the market?

In most cases, OK fabric is applied for orthopedics and sports braces. China Mainland OK fabric is widely used because of its friendly budget, meanwhile, its performance would meet quality requirements.

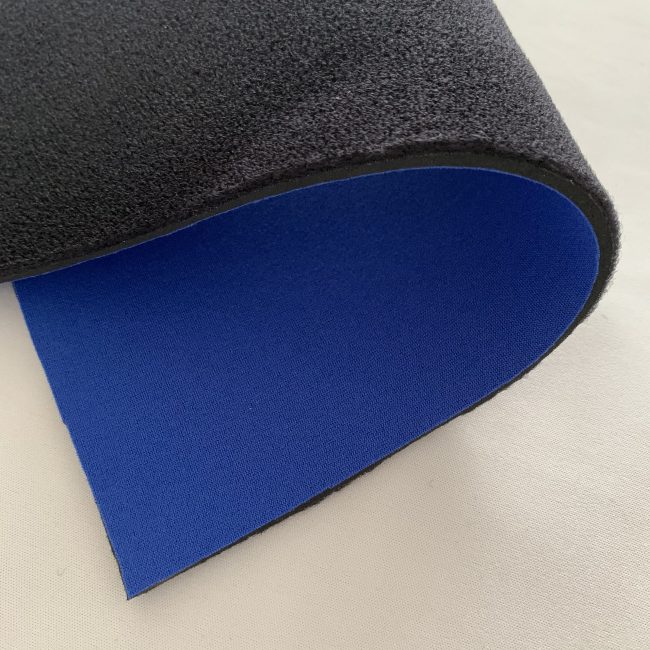

Can I order a custom colour?

Sure, please tell us the Pantone colour # you want, custom colour can be made based on that.

I am not sure about the neoprene fabric I am using? Can you check my samples?

Sure. We can test your samples and identify the neoprene fabric that works best for your products.

Can the fabric be UV resistance or waterproof?

Yes, no problem. UV resistance and water-repellent are often required for outdoor aqua sports. For particular use, special treatment will be made on the fabric, including waterproof glue that allows the lamination to stay firmly in seawater sports.

Do you offer free samples?

A4 size or so samples are free. If whole sheets or custom color is needed, small fee has to be charged.

Do you offer free samples delivery?

Unfortunately, no. A small fee has to be paid, which can be refunded from the first order. Economical shipping is available to minimize the delivery cost. Please contact us for the real-time shipping cost.

There essential factors about neoprene fabric?

- Neoprene Sponge Type

- The thickness of neoprene fabric, with/without fabric

- Fabric Lamination Type

The function of different combinations varies. It’s very important of understanding your application and choosing the materials that work best for your products. If you are not sure about how to choose the proper material, please feel free to contact us. We will help to recommend the best solution for your particular use.

Application of UBL Neoprene Fabric

Gallery of the uses of UBL Neoprene Fabric. Why UBL fabric? Why not other types of fabric? Consult us now!

Shoulder Braces

Knee Sleeves

Wrist Braces

Belly Band Holster

Animal Gear

Contact Vastop to Start Your Business

Choosing Neoprene Fabric can be easy and simple!

What we are delivering is more than products and services. Our core values include:

- Transparent communication;

- Custom design on demand;

- Optimized supply chain;

- Flexible service;

- Great Support for business growth.

Reach out to us for successful case studies!